Consultation

Choose low-carbon and enjoy a high-quality life

| Product Overview | |

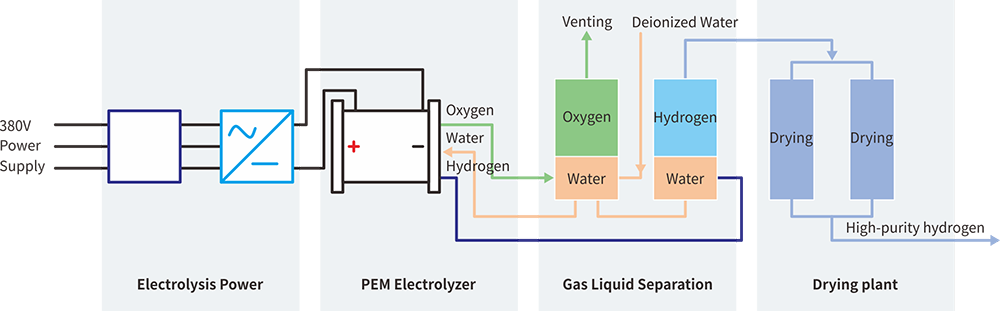

| ▪ Electrolysis of pure water to produce hydrogen, no corrosion, no pollution, high hydrogen purity; |  |

| ▪ Product modularity,different hydrogen output can be customized according to customer requirements, and provides professional suggestions; | |

| ▪ Membrane electrode production technology is mature, product performance is efficient with fast response and high current density; | |

| ▪ Strong ability to adapt to the site, can be tailored according to the site conditions and ensure the quality; | |

| ▪ Search key start/shutdown, emergency shutdown, real-time hydrogen leak detection, automatic fault detection system; depressurization; | |

| ▪ Adjustment range: 0-100% automatic adjustment; | |

| ▪ After-sales service, solve the customer's problem in time. | 2—10Nm³/h |

|

Indicator Model |

C— PEM-05 |

C— PEM-1 |

C— PEM-2 |

C— PEM-4 |

C— PEM-5 |

C— PEM-8 |

C— PEM-10 |

|

Hydrogen Outlet: Nm³/h |

0.5 |

1 |

2 |

4 |

5 |

8 |

10 |

|

Oxygen Outlet: Nm³/h |

0.25 |

0.5 |

1 |

2 |

2.5 |

4 |

5 |

|

Rated Power of electrolytic cell: kW |

2.4 |

5 |

10 |

20 |

27 |

39 |

55 |

|

Rated operating voltage: VDC |

24 |

50 |

100 |

36 |

48 |

70 |

38 |

|

Rated operating current: ADC |

100 |

100 |

100 |

560 |

560 |

560 |

1450 |

|

Hydrogen outlet pressure: MPa |

3 |

||||||

|

Oxygen outlet pressure: MPa |

normal |

||||||

|

Inlet water pressure: MPa |

≤0.2 |

||||||

|

Inlet water quality requirement |

ASTM 01193 Type I I Deionized water(< 1µS/cm, > 1MO·cm), propose ASTM 01193 Type I Deionized water(< 0.1 µS/cm, >10 MΩ·cm) |

||||||

|

Water Consumption: L/Nm³ |

0.95 |

||||||

|

Operation Temperature: ℃ |

45—65 |

||||||

|

Energy consumption: kW·h/m³ |

4.78 |

||||||

|

Energy efficiency |

74% |

||||||